In order to keep your business flowing like a well-oiled machine…. you need to have a well-oiled machine. As shops get busy and we tend to focus on customer repairs such as radiators and batteries, we often forget that our own tire equipment, lifts, air compressors and equipment need maintenance as well.

Tire Equipment Maintenance

We get a lot of phone calls from customers about their tire changers not working properly. Leaking water from hoses, cylinders working slow or getting stuck, bead breaker cylinder leaking air or the foot pedal spool valves stick or are leaking. The cause of most of these problems is from water getting into the air lines and into the internal machine components causing seals to dry up or parts to fail.

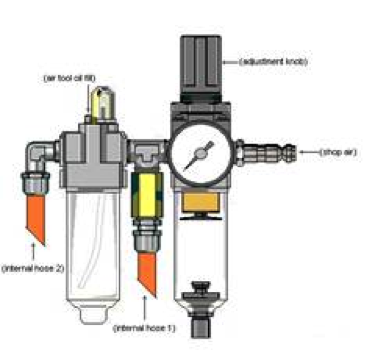

All of our tire changers come with a regulator assembly that includes a water separator and oiler. If the oiler is low or the water separator is full, the machine will not get proper lubrication.

On average an 80-gallon air compressor used to run a shop for 8-hours a-day can produce 3 gallons of water from condensation as a result of compressing air. This water makes it into the air lines and into our air tools and equipment.

Three simple steps to help keep your equipment up and running properly:

- Drain your air compressor daily or you can install a timed-release valve that will drain your tank hourly.

- Use a good quality air dryer setup installed after your compressor to keep moisture out of your air lines.

- Check your oiler assemblies weekly and fill when needed. Most use standard air tool oil. (check your equipment manual).

Like the cars we drive, Shop Equipment has recommended maintenance schedules and recommended fluids. Consult your manual for the recommended maintenance or contact your equipment dealer.

My ET etc960t turntable doesn’t want to turn motor goes table doesn’t

James, give our parts department a call to try and diagnose the issue and get it working for you! 800-336-2776.